NUOVA PATAVIUM Pipe Facing Machines (PFM) are the fastest cutting, most versatile and user-friendly machines on the market today. Years of experience with the highest quality components is what make our unit.

The machines are powered by a Hydraulic Power Unit (Diesel or electric engine) or a built in power take of other hydraulic circuit such as pipelayer/excavator (no adaptor needed).

The PFM machines are designed to machine the complex bevel required by automated pipeline welding systems; in addition, the machines can be used for:

- producing clean, bright, perfect bevels for manual pipeline welding to maximize quality and minimize repairs,

- machining modified bevels on heavy wall pipes to reduce metal volume, therefore reducing welding time;

- machining transition tapers or counter bores when joining pipes of different wall thickness.

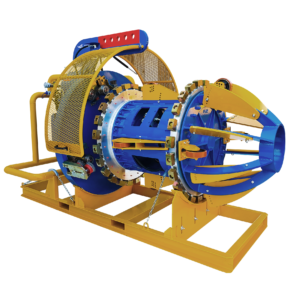

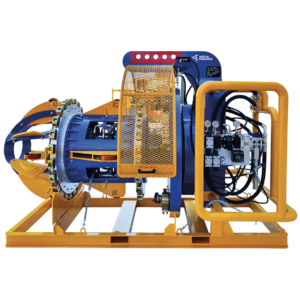

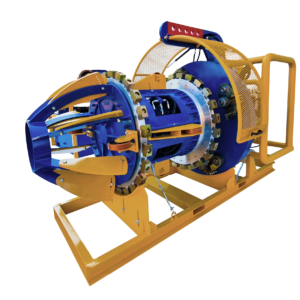

The machines have two major blocks, the clamping section and the machining section. The clamp section has two sets of hydraulically powered clamping shoes that are designed to work equally and simultaneously.

The PFM is secured to the pipe by expanding the clamp shoes inside the pipe.

The machining sections of the device consists of a rotating faceplate with four to six tool holders each holding tungsten carbide cutting tips.

Tools can be set a wide variety of bevel designs and wall thicknesses. Each tool holder may cut a different bevel angle simultaneously.

The PFM operation take from 2 to 6 minutes depending on pipe wall thickness and the experience of the operator.

The machine is delivered supplied with the following documentations:

USE AND MAINTENANCE MANUAL;

SPARE PARTS BOOK;

CE CERTIFICATION;

TEST REPORT.

External Brush Tool

Aggressive tool suited to heavy cleaning jobs and for brushing. It removes spatter, paint, rust, scale and other kinds of contamination, to expose the metal and coating.

Coating Removal Tool

Do you require the removal of plastic coating from protected pipes to allow weld testing prior subsea installation? The Coating Removal Tool enables you to cut thick plastic coating cleanly to allow exact measurements.

Tapering Tool

The Tapering Tool is the perfect solution when dealing with pipes of different thickness. It easily adjust the thickness of the pipes in order to create a secure join.

J-lay

The J-lay method is intended for deep-water pipeline installation. The pipe leave the lay system in the almost vertical position required for this installation type.

Container Box

A container box is available to store the PFM and accessories. It includes hooks for crane lifts and a packet for lifting with forklift.